Professor Seung Hwan Ko's Research Team at Seoul National University Develops Filter-Free Microbubble Air Purification System

Solves both fine dust and CO2 problems using water-based purification inspired by the human respiratory and circulatory systems

▲ (From left) SNUs Department of Mechanical Engineering researcher Seongmin Jeong (co-first author), Korea Institute of Science and Technology researcher Jaeho Shin (co-first author), and SNU Professor Seung Hwan Ko (corresponding author).

Seoul National University College of Engineering announced that a research team led by Professor Seung Hwan Ko from the Department of Mechanical Engineering has developed an eco-friendly air purification system using microbubble filters instead of conventional solid filters.

Enclosed indoor environments cause air pollution due to reduced oxygen and carbon dioxide accumulation, as well as fine dust and volatile organic compounds. In this case, ventilation carries the risk of introducing external contaminants, requiring more advanced purification methods.

The filters used in conventional air purification systems are unsuitable for enclosed rooms because they deteriorate due to the accumulation of fine dust and struggle to remove molecular substances, such as volatile organic compounds. Furthermore, the waste generated from filters that require regular cleaning and replacement has contributed to environmental pollution, highlighting the increasing demand for a new, eco-friendly air purification technology.

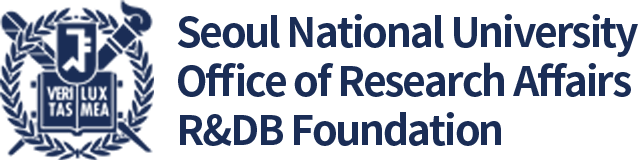

In response, the research team has developed a comprehensive air purification system inspired by the gas exchange principles of the human respiratory and circulatory systems. This innovative system not only removes indoor fine dust but also expels accumulated carbon dioxide and volatile organic compounds outdoors while supplying fresh oxygen to address oxygen deficiencies.

The human circulatory and respiratory systems prevent the entry of external pollutants while supplying oxygen to cells via the bloodstream and expelling unnecessary carbon dioxide. This process involves natural gas exchange in the alveoli and capillaries, effectively blocking the infiltration of fine dust. Simultaneously, waste materials are excreted through the kidneys, ensuring the body's efficient purification and detoxification mechanisms.

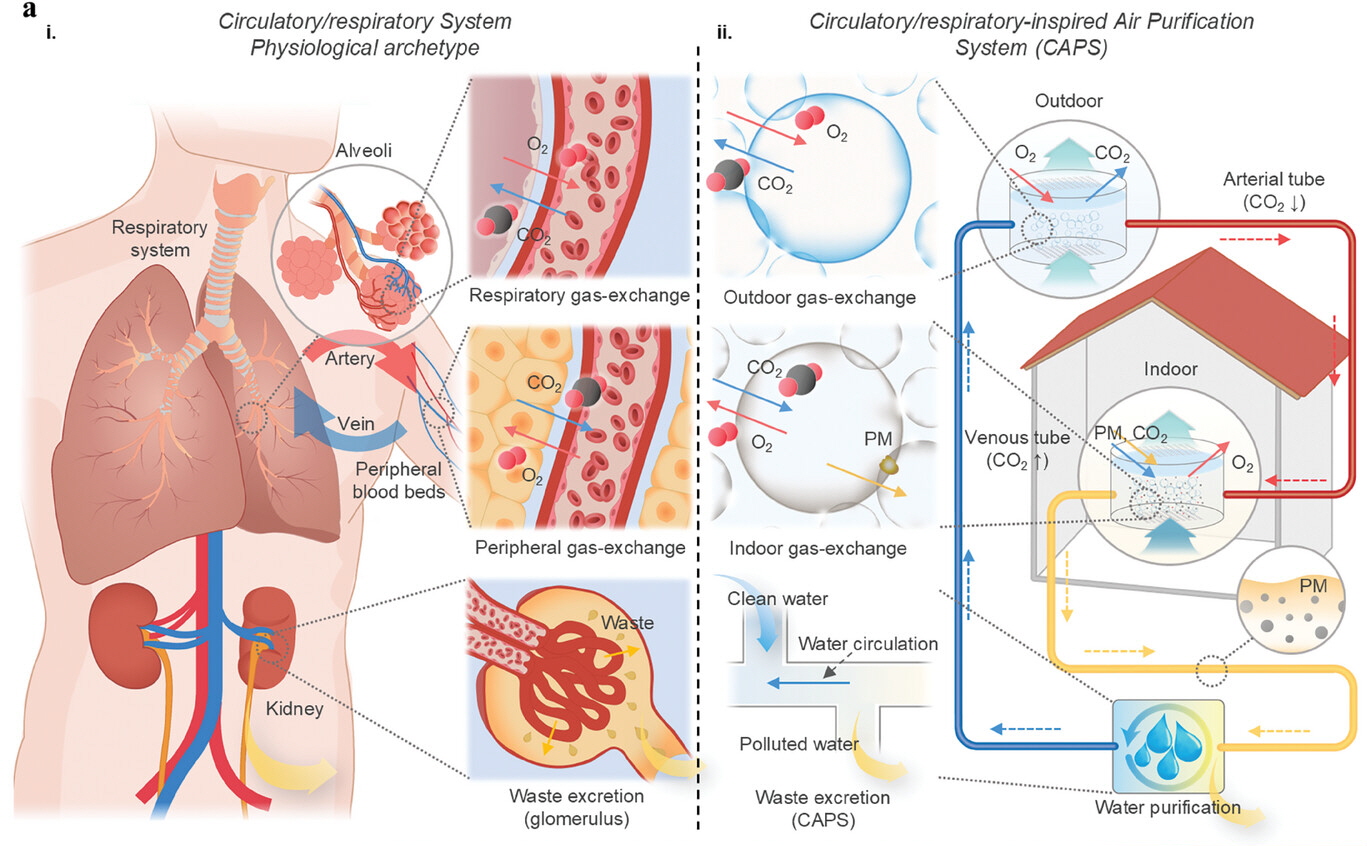

Inspired by this principle, the research team developed a water circulation system that mimics blood circulation. Through this innovation, they demonstrated the ability to maintain normal carbon dioxide levels in indoor air. Additionally, they proved that an elastic filter, developed using laser technology, can generate smaller and more uniform microbubbles compared to traditional bubble production methods.

The microbubble-based gas exchange system features a simple principle and structure, enabling easy scalability by increasing the size or number of devices. The research team experimentally demonstrated its applicability across a range of settings, from compact tabletop and vehicle-mounted units to larger spaces such as offices and conference rooms.

Professor Seung Hwan Ko said, “This environmentally friendly technology, which replaces traditional filters with a simple water-based mechanism, purifies both particulate and molecular pollutants without generating filter waste, providing a sustainable alternative to existing filtration systems.”

The results of the research, which was supported by the Ministry of Science and ICT and the National Research Foundation of Korea, were published on October 10 in Advanced Materials, an internationally renowned journal in the field of materials.

Figure 1. Conceptual configuration of an air filtration system simulating the human circulatory system/respiratory tract

Schematic representation of gas exchange and waste removal processes within the human body (left). Schematic of a circulating air filtration system with a similar structure to the human body (right).

Figure 2. Actual configuration of an air filtration system simulating the human circulatory system/respiratory tract

(a) Schematic of a circulating air purification system consisting of water, a gas exchange unit, and a circulation pump.

(b) Structure of the gas exchange unit and elastic micro-pore filter using microbubbles.

(c) Actual appearance of the MEF and an optical‐microscope image showing the micro‐holes array within the MEF

(d) Photograph taken with an ultra-high-speed camera during actual microbubble generation.

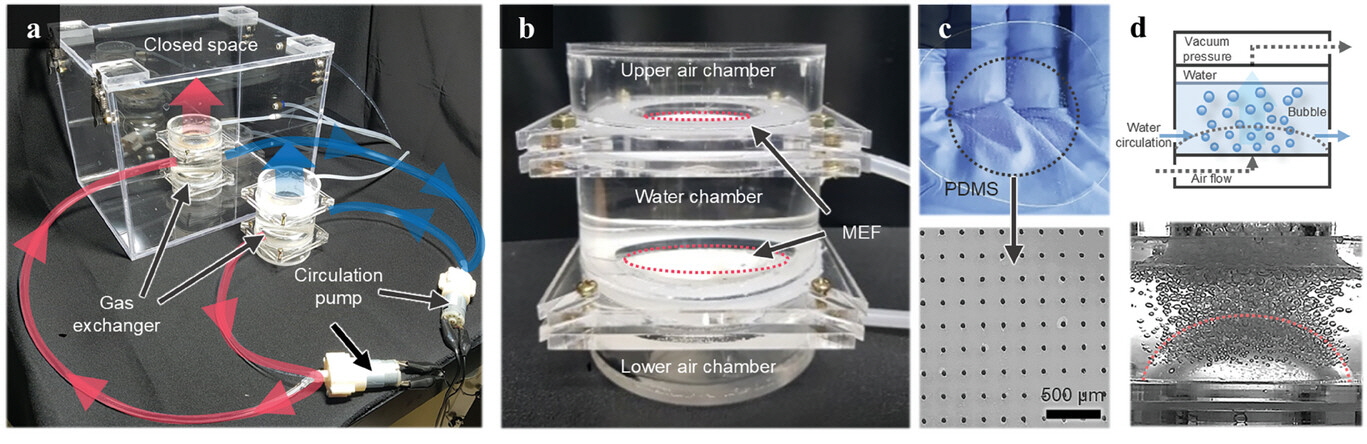

Figure 3. Evaluation of particulate matter and CO2 removal performance of human-simulated circulating air purification systems

(a) Photograph of the particulate matter (PM) removal process in an enclosed space.

(b) Filter efficiency measurement results for different PM sizes.

(d) Photo of CO2 removal process in an enclosed space.

(f) Measurement of CO2 removal performance as a function of water circulation rate.

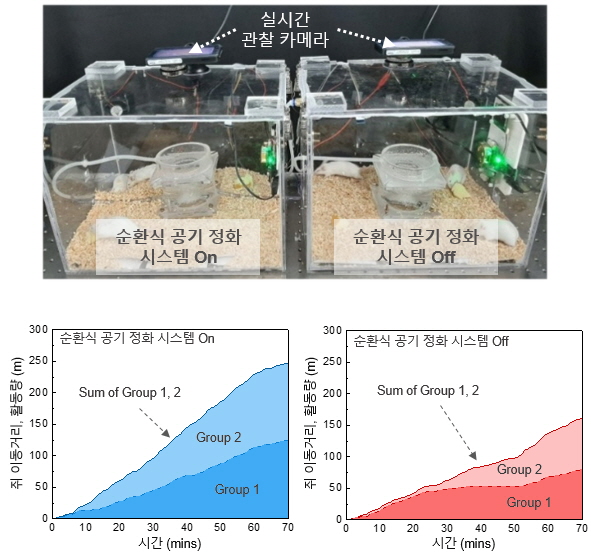

Figure 4. Animal test to identify and resolve the problem of indoor oxygen deprivation/carbon dioxide buildup due to breathing (top). Measured activity of rats with and without a circulating air purification system (bottom).